|

|

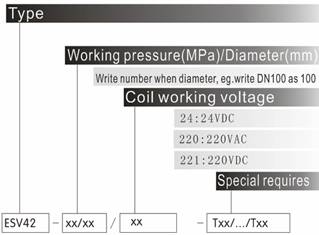

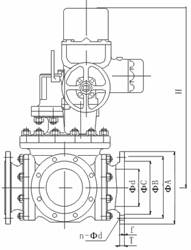

ESV42 electric four-way reversing valve |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

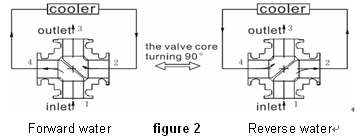

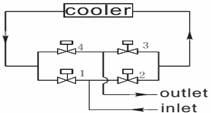

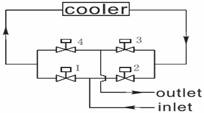

Characteristics: Simple structure, easy operation, easy maintenance. Profile: ESV42 electric four-way reversing valve is designed for the power station unit cooler’s water is provided by forward and reserve circulation, in order to prevent the clogging of the cooler caused by one-way water. Traditional crafts take four electric valves piping as Figure 1 to realize the cooler reverse circulation water, which takes a large space and cost a lot, and every turning should take operation of four valves.

When forward water, valve 1 and 3 are open, valve 2 and 4 are closed, while reverse water, valve 2 and 4 are open, valve 1 and 3 are closed.

Forward water figure 1 Reverse water The working principle of ESV42 electric four-way reversing valve which is replacing the process piping and valve group is as Figure 2.

ESV42 electric four-way reversing valve is designed for the special craft of forward and reverse watering, the function is very useful and reliable. The structure of top-loading fixed ball and four-side seat valve core structure makes it sealing well, resistance gravel wear and lasts long. Electric operation (manual operation is also available) makes it convenient to control because the information channel and operation interface is among the control box, valve and PC. It can also realize the auto change of normal and reverse water over time according to the process requirements. The main parameters:

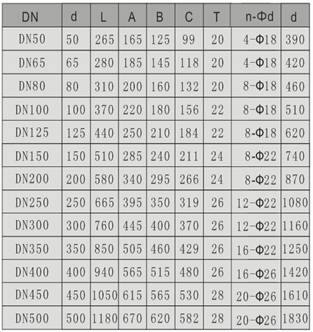

PN10 dimensions

PN16 dimensions

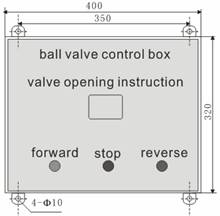

Introduction of control system:

Parts that the control box contains Control box material and size

1.Open button: forward water Material: cold rolled steel

2.Close button: reverse water Box thick: 200mm

3.Stop button: stop Mounting plate: galvanization

4.Forward water indicator Surface treatment: enamel painted

5.Reserse water indicator

6.The median action indicator (flicker)

7.Valve opening instruction

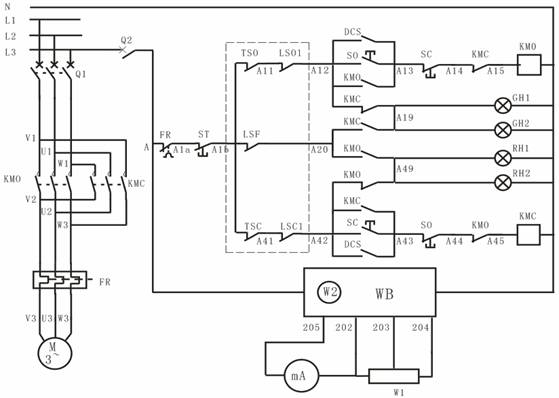

Electrical wiring diagram:

Control system electrical parameters

Product Standard Table:

Particular Requirements for Product List:

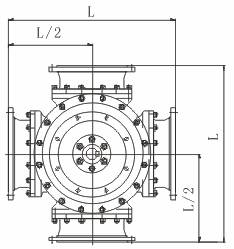

Structural dimensions:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||